The pharmaceutical industry operates under strict quality and safety standards. Every component in the production process must ensure purity, precision, and compliance with regulatory norms. Valves, being critical to fluid handling, directly influence product quality and safety. Traditional valves, however, often struggle with leakage, contamination risks, and frequent maintenance. This is where Bellow Seal Valves play a vital role, providing leak-proof performance, contamination-free operations, and long-term reliability.

Challenges in the Pharmaceutical Industry

Pharmaceutical manufacturing requires stringent control over fluids, gases, and steam used in various processes. Even a minor leak can compromise product quality or violate compliance standards.

Common challenges include:

-

Risk of Contamination: Leaks or emissions can contaminate sensitive formulations.

-

Regulatory Pressure: Compliance with cGMP, FDA, and WHO norms demands zero leakage systems.

-

High Purity Requirements: Valves must not react with or alter the product.

-

Operational Downtime: Frequent valve failures can disrupt critical production schedules.

These challenges highlight the need for valves that combine precision, safety, and durability.

The Role of Bellow Seal Valves

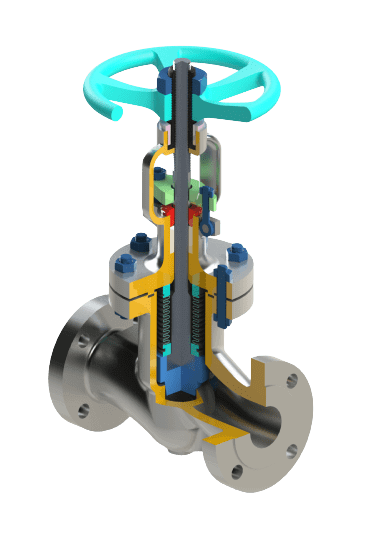

A Bellow Seal Valve incorporates a metallic bellows that ensures a hermetic seal between the stem and the process medium. This design eliminates leakage, making it highly suitable for pharmaceutical environments where safety and purity are paramount.

Key Features:

-

Leak-Free Operation: Ensures zero stem leakage.

-

Sterile Design: Supports clean and contamination-free production.

-

Durability: Handles high-pressure and high-temperature conditions in sterile steam lines.

-

Regulatory Compliance: Designed to meet pharmaceutical validation standards.

Applications in Pharmaceutical Processes

Bellow Seal Valves are deployed in critical pharmaceutical applications such as:

-

Pure Steam Distribution: Ensures sterile supply of steam without risk of leakage.

-

Water for Injection (WFI) Systems: Prevents contamination in ultra-pure water pipelines.

-

Chemical Dosing Lines: Provides safe handling of cleaning agents and solvents.

-

Fermentation & Biotech Processes: Maintains sterile and controlled environments.

These applications demonstrate the valves’ role in protecting product quality and ensuring patient safety.

Benefits for the Pharmaceutical Industry

The adoption of Bellow Seal Globe Valves and Gate Valves brings several advantages to pharmaceutical operations:

-

Zero Contamination Risk: Leakage-free design ensures product purity.

-

Regulatory Compliance: Helps meet global pharmaceutical standards.

-

Operational Reliability: Reduces downtime in critical production stages.

-

Extended Service Life: Low maintenance requirements improve cost efficiency.

-

Worker Safety: Protects operators from exposure to harmful cleaning chemicals.

Why Bellow Seal Valves Are Preferred in Pharma

Unlike conventional valves, Bellow Seal Valves provide both precision flow control and contamination-free operations, making them indispensable for pharmaceutical manufacturing. Their ability to handle pure water, pure steam, and critical fluids without compromise ensures compliance and reliability.

With the growing global demand for high-quality medicines, pharmaceutical companies are investing in advanced technologies that guarantee safety and efficiency — and Bellow Seal Valves perfectly meet these expectations.

Conclusion

In an industry where safety, quality, and compliance are critical, Bellow Seal Valves provide unmatched reliability. By eliminating leakage, ensuring product purity, and meeting stringent international standards, these valves safeguard both production processes and end-user health.

For pharmaceutical companies committed to quality and safety, Bellow Seal Valves are an essential investment.

Freture Techno Pvt. Ltd., a leading manufacturer of Bellow Seal Valves in Mumbai, India, delivers advanced valve solutions trusted by pharmaceutical manufacturers worldwide.