Bellow seal control valve stands out for its ability to provide effective sealing and control in critical operations. This article delves into the features, advantages, and common pain points associated with low-quality valves, emphasizing the importance of choosing the right product for specific applications. In various industrial applications, the significance of using reliable and high-quality valves cannot be overstated.

Understanding Bellow Seal Globe Control Valves

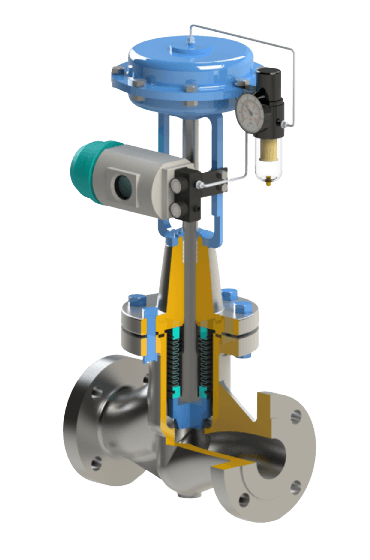

It is designed to regulate fluid flow in a system while minimizing leakage. The valve features a flexible metallic bellow that serves as a barrier between the fluid and the external environment, thus preventing any leakage. This design is especially beneficial in applications involving hazardous or corrosive fluids, where leakage can pose significant risks to both safety and the environment.

|

| Bellow Seal Globe Control Valve |

Key Features

Leak-Proof Design: The primary advantage of this valve is their leak-proof design. The metallic bellow acts as a seal, preventing any fluid from escaping, which is crucial in applications where contamination must be avoided.

Durability: Constructed from robust materials, they are engineered to withstand high pressures and temperatures. This durability ensures a longer lifespan compared to standard valves, reducing the need for frequent replacements.

Precision Control: These valves are designed for precise flow control. They enable operators to adjust the flow rate accurately, ensuring optimal performance in various processes.

Low Maintenance: Due to their reliable sealing mechanism, the valves require less maintenance than traditional valves. This feature leads to reduced downtime and operational costs.

Versatile Applications: They are suitable for various industries, including chemical processing, pharmaceuticals, oil and gas, and power generation. Their versatility makes them an excellent choice for numerous applications.

Pain Points of Low-Quality Valves

Despite the advantages of using these valves, many industries still face challenges related to low-quality valves. Understanding these pain points can help organizations make informed decisions when selecting valve solutions.

1. Leakage Issues

One of the most significant problems associated with low-quality valves is leakage. Poor sealing can lead to fluid escaping from the system, resulting in contamination, environmental hazards, and potential safety risks. In industries dealing with hazardous materials, leakage can have severe consequences.

2. Frequent Replacements

Low-quality valves often have a shorter lifespan, leading to frequent replacements. This not only increases operational costs but also disrupts production processes. The need for regular maintenance and replacement can strain resources and affect overall efficiency.

3. Inaccurate Flow Control

Valves that do not perform well can lead to inaccurate flow control. In applications where precise measurements are crucial, such as in pharmaceuticals or chemical processing, inaccurate flow can result in product quality issues and regulatory non-compliance.

4. Increased Downtime

When low-quality valves fail, downtime can become a significant concern. Unscheduled maintenance and repairs can halt operations, leading to lost productivity and revenue. The impact of downtime extends beyond immediate financial losses, affecting customer satisfaction and market competitiveness.

5. Safety Hazards

Using low-quality valves increases the risk of safety hazards. In high-pressure systems, valve failure can lead to catastrophic accidents. Ensuring reliable performance is essential for maintaining a safe working environment and protecting personnel.

Investing in high-quality bellow seal control valves can address the pain points associated with low-quality alternatives. The leak-proof design, durability, and precision control offered by these valves make them an ideal choice for industries requiring reliable performance.

When selecting a Bellow seal Globe control valve, it is essential to consider the manufacturer's reputation and product specifications. Freture Techno Pvt. Ltd. is a leading Bellow Sealed Globe control valve. With a commitment to quality and customer satisfaction, We offer reliable solutions to meet the diverse needs of various industries.

For reliable and high-performance bellow seal control valves, choose Freture Techno Pvt. Ltd. to ensure optimal operation and safety in your processes.

No comments:

Post a Comment