In the world of industrial fluid control, the Bellow Sealed Globe valve has emerged as a critical component for systems that demand precision, reliability, and leak-free operation. These valves are designed to offer excellent sealing performance in high-pressure and high-temperature environments, making them indispensable in sectors ranging from chemical processing to power generation.

What is a Bellow Sealed Globe Valve?

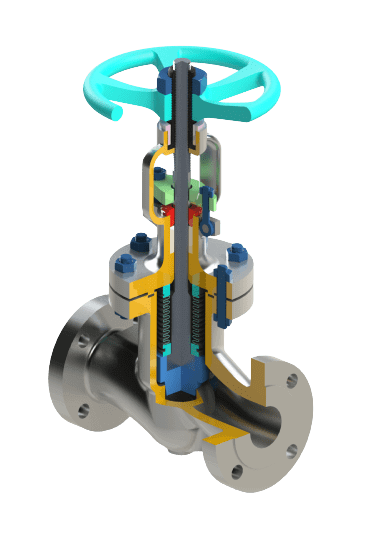

The valve is a specialized type of valve that incorporates a flexible bellow as its sealing element. Unlike conventional valves that rely solely on traditional packing materials, the bellow provides a dynamic seal that effectively prevents leakage. The globe valve’s inherent design allows for precise flow regulation, while the bellow element ensures that even under extreme conditions, the seal remains intact. This unique combination of design features enhances the overall performance of the valve, making it suitable for critical applications where safety and efficiency are paramount.

|

| Bellow Sealed Globe Valve by Freture Techno |

Key Features and Benefits

Enhanced Sealing Capability:

The primary advantage of a these Globe valve is its superior sealing performance. The integrated bellow adapts to changes in pressure and temperature, maintaining a tight seal that minimizes the risk of leaks. This is particularly important in processes involving hazardous or corrosive fluids, where any leakage could lead to severe safety and environmental consequences.

Precise Flow Control:

Globe valves are renowned for their ability to regulate flow with high accuracy. The bellow sealed design further refines this control by reducing the effects of thermal expansion and vibration. This means operators can adjust flow rates with confidence, ensuring that systems run smoothly and efficiently.

Durability and Longevity:

Industrial environments often subject valves to harsh conditions, including extreme temperatures and corrosive substances. The Bellow Valve is engineered with robust materials and construction techniques that resist wear and tear. This durability translates into a longer service life, reducing the frequency of maintenance and replacement, and ultimately lowering overall operational costs.

Minimal Maintenance Requirements:

One of the key selling points of Bellow Sealed Globe valves is their reduced need for routine maintenance. The bellow’s ability to maintain a consistent seal minimizes the wear on other valve components, which in turn reduces the likelihood of unexpected breakdowns. For industries where uptime is critical, this means fewer disruptions and increased productivity.

Adaptability Across Industries:

From petrochemical plants and water treatment facilities to power generation stations, the versatility of the bellow sealed globe valve makes it a preferred choice in a wide range of applications. Its design is adaptable enough to handle various fluid types and process conditions, making it a universal solution for many industrial challenges.

Applications in Modern Industry

The Globe Valves are integral to systems where precision and reliability cannot be compromised. In the chemical processing industry, these valves help control the flow of reactive substances, ensuring that processes remain safe and efficient. In power plants, they regulate steam and water flow, playing a vital role in maintaining system stability and performance. Additionally, in water treatment and waste management systems, the valves provide the necessary control to prevent contamination and ensure compliance with strict regulatory standards.

Innovations and Future Trends

The evolution of industrial automation and digital monitoring has paved the way for smarter, more integrated valve systems. Modern Bellow Sealed Globe valves are now often equipped with sensors that provide real-time data on pressure, temperature, and flow rates. This integration with the Industrial Internet of Things (IIoT) allows for predictive maintenance and improved process control. By monitoring performance continuously, operators can anticipate issues before they become critical, thereby enhancing operational efficiency and safety.

Conclusion

The Globe valve is a prime example of engineering innovation meeting practical industrial needs. Its superior sealing capability, precise flow control, durability, and low maintenance requirements make it a cornerstone in modern industrial processes. As industries continue to demand higher efficiency and safety standards, the role of advanced valve technologies like the Bellow Sealed Globe valve will undoubtedly grow. For engineers and facility managers looking to optimize their systems, investing in these valves offers a pathway to improved performance and long-term operational cost savings.

With continuous advancements in materials and sensor technology, the future of These Globe valves is promising. They will continue to play a vital role in ensuring that industries operate at peak efficiency, providing the secure, reliable, and precise control that modern processes require. Whether you are involved in chemical processing, power generation, or water treatment, understanding and utilizing the benefits of these Globe Valves can be a game changer for your operations.

No comments:

Post a Comment