Bellow sealed Globe Valves have become a vital component in various industries where control of fluid flow, pressure, and temperature is critical. Their unique design, which includes a bellows system to seal the valve stem, offers enhanced performance over conventional valves, particularly in environments where leakage prevention, safety, and environmental protection are paramount. These valves find extensive use in industries such as oil and gas, chemical processing, pharmaceutical manufacturing, and power generation.

|

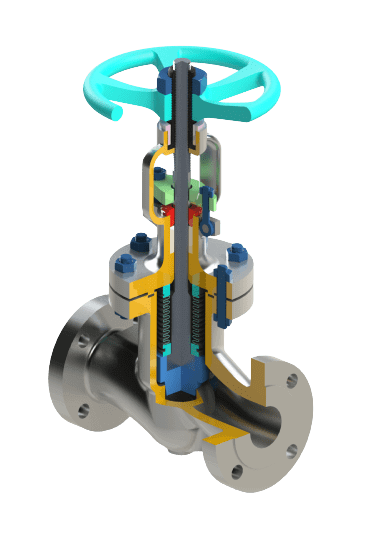

| Bellow Globe Valve |

How Bellow Sealed Globe Valves Work

A globe valve is a type of linear motion valve used for regulating fluid flow in a pipeline. It consists of a movable disk-type element and a stationary ring seat within a spherical body. When the valve is closed, the disk moves against the flow, creating a seal that prevents the passage of the medium. In traditional globe valves, the stem packing can wear out over time, leading to leakage, especially in high-pressure or high-temperature environments.

The bellows assembly in a bellow sealed globe valve serves as an alternative to conventional stem sealing methods. The bellows, typically made from stainless steel or other corrosion-resistant materials, expand and contract as the valve stem moves. This creates a hermetic seal, ensuring zero leakage to the atmosphere, which is particularly beneficial in handling toxic or hazardous substances. By eliminating the need for traditional packing, these valves offer superior longevity, reduced maintenance, and an enhanced safety profile.

Key Features and Benefits of Bellow Sealed Globe Valves

Zero Emission and Leak Prevention

The most significant advantage of bellow sealed globe valves is their ability to provide zero emission operation. Traditional globe valves can leak over time due to wear and tear of the stem packing. In contrast, bellow sealed valves use a flexible metal bellows welded to the valve stem, ensuring a hermetic seal that prevents any leakage. This feature is particularly crucial in industries handling volatile chemicals, toxic gases, or steam, where even minor leaks can pose significant safety hazards.Extended Service Life

The bellows in these valves are designed to withstand thousands of cycles of operation without failure. This reduces the frequency of maintenance, especially in harsh operating conditions such as high temperature or pressure environments. The bellows protect the stem from exposure to corrosive fluids, which in turn enhances the valve's lifespan compared to conventional globe valves.Environmental Compliance

With growing emphasis on environmental regulations, industries are under pressure to reduce fugitive emissions. Bellow sealed globe valves are designed to meet stringent environmental standards like ISO 15848, which governs the performance of industrial valves in controlling emissions. Their zero-leakage design helps industries comply with these regulations, making them an environmentally friendly choice.Safety and Reliability

In industries where the handling of hazardous chemicals and high-pressure steam is involved, safety is a top priority. The hermetically sealed design of these valves prevents any leakage, significantly enhancing plant safety. Additionally, since the bellows act as a double seal, even if the outer sealing fails, the bellows will prevent any medium from escaping, offering an extra layer of protection.Low Maintenance Costs

Due to their robust design, bellow sealed globe valves require less frequent maintenance than conventional valves. The elimination of stem packing also reduces wear and tear. This minimizes the need for regular inspections and costly downtime, contributing to higher overall efficiency and reduced operational costs.

Applications of Bellow Sealed Globe Valves

Bellow sealed globe valves are widely used in applications where stringent sealing is required to prevent leakage. They are commonly found in:

Pharmaceutical Industry: These valves are crucial in ensuring the purity of processes, especially when handling sterile fluids or gases. The zero-leakage design is essential in maintaining the integrity of pharmaceutical products.

Chemical and Petrochemical Plants: In industries dealing with aggressive chemicals, corrosive fluids, and toxic substances, bellow sealed valves help to prevent leakage and protect personnel and the environment from harmful exposures.

Power Generation: In power plants, especially those using steam as a working fluid, bellow sealed globe valves are used to control steam flow with minimal leakage, ensuring efficient energy conversion and safe operations.

Oil and Gas Industry: Bellow sealed globe valves are widely employed in refining and gas processing facilities to control the flow of hazardous substances, ensuring safe and leak-free operations under extreme pressure and temperature conditions.

Factors to Consider When Choosing a Bellow Sealed Globe Valve

Material Selection

The body and bellows material should be compatible with the fluid being handled. Stainless steel is often preferred for its corrosion resistance, but other materials like Inconel or Hastelloy may be used in highly corrosive environments.Pressure and Temperature Ratings

Bellow sealed valves are available in a wide range of pressure and temperature ratings. Selecting a valve that can handle the maximum pressure and temperature in the application is crucial for reliable operation.Size and Flow Capacity

The valve size and flow coefficient (Cv) should match the system’s requirements to avoid inefficiencies in fluid handling or excessive pressure drops.Design Standards

Ensure the valve conforms to relevant industry standards, such as ISO or API, to guarantee its suitability for the intended application and compliance with regulatory requirements.

Buy Bellow Sealed Globe Valves from Freture Techno Pvt. Ltd.

If you're in the market for high-quality Bellow sealed Globe valves, Freture Techno Pvt. Ltd. is a leading manufacturer based in Mumbai, India. With a focus on engineering excellence, Freture Techno Pvt. Ltd. produces reliable and robust bellow sealed valves that meet the demands of various industries. Their valves are designed for superior performance, safety, and environmental compliance, making them the ideal choice for your industrial needs.