Leakage in any fluid system can have detrimental effects, compromising safety, efficiency, and the environment. Leakage valves, therefore, play a crucial role in controlling and preventing leaks, ensuring a seamless and secure operation in various industries. In this exploration, we'll shed light on the significance of leakage valves and delve into the workings of Bellow sealed Globe valves—a key player in leak prevention.

Understanding Leakage Valves

Leakage valves, as the name suggests, are designed to manage and mitigate leaks in fluid systems. Whether dealing with gases, liquids, or chemicals, leakage valves act as a barrier, preventing unwanted escape of the substance being transported. This not only ensures the preservation of resources but also maintains the safety of the working environment.

There are various types of leakage valves, each tailored to specific applications and fluid types. Common leakage valve types include ball valves, gate valves, check valves, and, notably, High Pressure Bellow seal Globe valves.

Bellow Seal Globe Valves: A Leak-Free Solution

Among leakage valves, Bellow Sealed Globe Valves stand out for their exceptional leak-tight capabilities and versatile applications. These valves derive their efficiency from a unique sealing mechanism involving a bellows-like structure.

The Valve Structure:

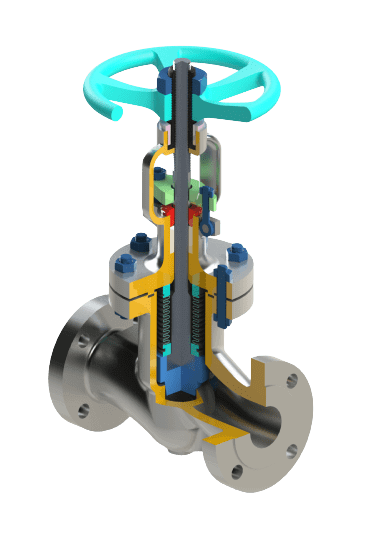

Bellows: The distinctive feature of a bellow seal globe valve is the bellows—a collapsible, accordion-like structure made of robust materials such as metal alloys. This bellows structure provides a flexible yet robust seal that expands and contracts in response to pressure and temperature changes.

Valve Body: Housing the bellows, the valve body provides the necessary structure for the valve to function effectively.

Stem and Actuator: Connecting to the bellows, the stem and actuator enable precise control over the valve's opening and closing, ensuring optimal flow management.

Seat: The sealing surface that makes contact with the bellows, forming a tight and reliable seal.

|

| Bellow Sealed Globe Vave Manufacturers |

Operational Mechanism:

Closing the Valve: Activating the actuator collapses the bellows, pressing the sealing surface (bellows) onto the seat, effectively shutting off the fluid flow and preventing any leaks.

Opening the Valve: Reversing the actuator's motion expands the bellows, lifting the sealing surface away from the seat, enabling fluid flow.

The bellows, being the heart of the mechanism, are responsible for the leak-free nature of Bellow Seal globe valves.

Advantages of Bellow Sealed Globe Valves

Bellow Seal Globe valves offer several advantages, making them a preferred choice in fluid control systems:

Exceptional Leak Prevention: The bellows mechanism ensures an airtight seal, preventing any leakage and enhancing operational safety.

Extended Durability: The bellows protect the stem from direct contact with the fluid, enhancing the valve's lifespan by reducing corrosion and wear.

Broad Application Spectrum: Bellow Sealed Globe Valves are versatile and find applications in diverse industries, including pharmaceuticals, chemicals, water treatment, and more.

High Pressure and Temperature Handling: These valves are designed to operate efficiently even under extreme pressure and temperature conditions, making them suitable for demanding environments.

Leakage valves, especially Bellow Seal Globe Valves, are indispensable components in industries where fluid control is paramount. The innovative design and mechanism of Bellow Valves provide a leak-free solution, ensuring the integrity of fluid systems and maintaining a safe and efficient operational environment. By opting for Metal Bellow Sealed Globe valves, industries can effectively mitigate leakage concerns and focus on streamlined and reliable fluid management.

No comments:

Post a Comment